carbon steel (f.e. S355J2G3)

EN 10025

quenched steel (f.e. 42CrMo4, C45)

EN 10083

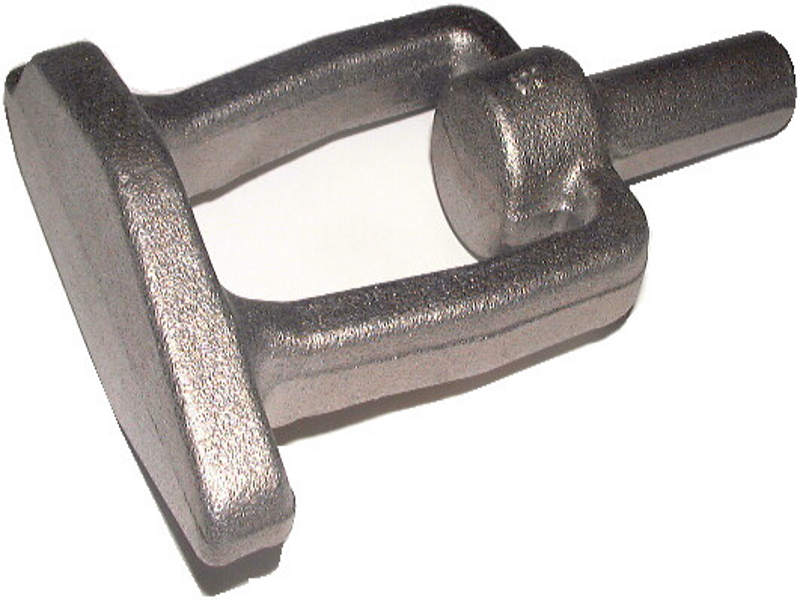

steel forgings

0,5 - 25 kg

aluminum forgings

< 35 kg

brass forgings

< 400 kg

All ductile metals are suitable for drop forging. Steel is relevant in this case because many standardised types with different properties are available. These properties can be adjusted to most different requirements as well as they can be affected in wide ranges by forming and heat treating.

Non-ferrous metal are used considerably less, as measured by steel.

Technically relevant are aluminium and copper alloys as well as titan materials in specific fields.

Checkings

- dimensional

- chemical analysis

- mechanical properties (Rm, Re, A, HB, KV ...)

- nondestructable testings (US-, X-ray-, MP_, penetration test)

- Metallographie

Approvals

- inspection certificates acc. to EN 10204 3.1 or 2.2

Certifications

- ISO 9001:2000 oder TS 16949

- DNV, LRS, GL

- AD 2000 W0

- Deutsche Bahn

Surface treatment

- priming or painting (KTL also)

- coating

- galvanizing